https://www.cnn.com/2019/03/31/media/jeff-bezos-gavin-de-becker-saudi-arabia-leak/index.html

2019-03-31 22:10:00Z

52780255188841

March 31st, 2019 by Zachary Shahan

I’ve followed Tesla closely for about 7 years. Confident predictions about Tesla’s imminent death have been commonplace for much longer than that. These have come from armchair auto experts, retired auto executives, non-retired auto execs, high-rolling short sellers, low-rolling short sellers, clueless or pretending to be clueless TV hosts and journalists, paid trolls, and probably others I’m forgetting to honor here.

I’m not sure when the first prediction of bankruptcy or startup death was made, but the start of an infamous “Tesla Death Watch” was on May 19, 2008. Something crossed my mind recently — why not have some fun with this never-ending hype? Why not toy a bit with the ongoing smear campaigners and have some good-hearted fun in the process?

The idea that popped into my head was, let’s start a Tesla death anniversary celebration!

A follow-up reaction from Elon to our idea, after he thought about it for a few seconds. Again, this is not a screenshot from the Tesla Model Y reveal event. Do not try to compare this image to any portion of the Tesla video from that event.

The event idea is simple. We encourage any and all Tesla owners and fans to start or join Tesla celebrations on May 19, 2019. If you are interested in starting or joining one with our support, jump over to our contact form and choose the option “I want to host or join a Tesla 11 Year Death Anniversary event!“

If you are not sure yet, take your time to think about it — you have two and a half months to consider it and make plans. But seriously, come on, what is there to think about?!

That’s basically all there is to it. We are going to encourage hosts to focus on test drives and showing off the supersplendulous Tesla Model 3, Model X, Model S, and Roadster, but it’s really up to hosts and participants how they decide to celebrate. You could host a house party, a pool party, or a Tesla camping party.

You could launch an epic road trip, organize a Tesla parade, plan a day off Tesla drag racing, or create a Tesla scavenger hunt.

You could have a frunkpuppy party, organize a day of pranks using Tesla Summon, or try to set a record for the highest number of dancing Model Xs.

I’m sure there are many ingenious ideas Tesla owners and fans could come up with to celebrate Tesla’s 11th death anniversary. The only thing I can’t understand is why anyone wouldn’t host or join a Tesla death anniversary event.

To further get you in the mood, I’m going to repost below three of my favorite articles from our Tesla Flashbacks series. Enjoy!

August 29th, 2018

10 years ago, now-rabid CNBC didn’t know Tesla from your mother. Fox News was busy complaining that Obama encouraged people to keep their tires well inflated. Seeking Alpha? Well, I couldn’t find a single Tesla story on Seeking Alpha published in the month of August 2008. But some geniuses on a website called “The Truth About Cars” were onto something. They published episode #17 of their “Tesla Death Watch.”

10 years ago, now-rabid CNBC didn’t know Tesla from your mother. Fox News was busy complaining that Obama encouraged people to keep their tires well inflated. Seeking Alpha? Well, I couldn’t find a single Tesla story on Seeking Alpha published in the month of August 2008. But some geniuses on a website called “The Truth About Cars” were onto something. They published episode #17 of their “Tesla Death Watch.”

Here’s the core of that insightful post:

“They’re heading for their promised 100 cars per month. You know; once they get their transmission shit together. in October. Or thereabouts. Or later. Meanwhile, according to a Tesla newsletter released Wednesday night, the Lotus assembly plant in Hethel, England has fifteen cars ‘ready to be shipped’ to CA sans battery and powertrain. I’ll admit it: fifteen cars is fourteen more than I’ve built (don’t ask). But have you seen Tesla’s showroom? These Silicon Valley boys are not exactly Scrooge McDuck when it comes to overheads. Even if you figure each customer car at the new price of $120k, that’s only $1.8m gross income. What’s the bet that each of those cars will end up costing Tesla money (a la David Brown’s Aston Martin era)? Never mind. Saving the planet is a tough job, but someone’s got to do it.”

Talk about some smart cookies, eh? They really saw what was up. Tesla was doomed. It certainly couldn’t build cars. And it didn’t know how to manage money. And if Tesla build cars, those cars would surely cost more to build and market than customers would pay for them. Well, too bad — Tesla might have built some fun cars if it had survived.

Episode #16 was published a week before. Here’s a snippet from that:

“Now, if Tesla can just amp-up production, not ‘fad out,’ keep costs under control (have you seen that showroom?), raise more money, build a more profitable product and fend off competitors, we can take them off the Death Watch.”

Ha. Clever. Funny. Insightful. Spot on the money. Of course Tesla couldn’t do any of those things. Good thing the brave souls at “The Truth About Cars” were calling a spade a spade.

Oh, wait — Tesla didn’t die in 2008?

Oddly, not only did it not die, but some of the same contributors to the Death Watch blog continue to claim that Tesla will collapse any day. (Note: They no longer write on “The Truth About Cars.” In fact, their credibility has graduated some of them to even bigger websites.)

Here’s a piece of a 2008 post from one of the thoughtful critics who continues to proudly proclaim imminent doom for Tesla:

“Tesla Motors says it’s secured 90 acres between San Jose and Santa Clara, CA to build its world headquarters. Oh, and production facilities for its (supposedly) upcoming Model S (nee White Star) sedan. The announcement is creating all kinds of excitement among the kind of people who use terms like ‘green collar jobs’ and ‘cleantech.’”

Silly hippies.

The blogging crew also did some community service admonishing Megan Fox for talking about the Tesla she’d buy someday. “Anyway, your money’s no good at Tesla, Megan. And therein lies the tale.” That’s right, it’s just a dream, because Tesla can’t build cars, ya know?

Oh, I forgot a great episode. Back in July 2008, the car boys piggybacked on the always brilliant and helpful New York Times (yes, that New York Times). Here’s a quote from the piece in the Times:

“Just because Tesla has succeeded in making an expensive electric sports car does not mean that it will be able to make a moderately priced five-seat sedan. The latter is a quantum leap more difficult… David Cole, the chairman of the Center for Automotive Research, is another Tesla skeptic. For one thing, he says, the battery solution in the Roadster probably won’t work in a heavier car. ‘Lithium batteries are going to change the world,’ he said, ‘but they are not ready for prime time.’ Tesla’s solution in the Roadster — tying together thousands of small batteries into one giant one — is ‘suboptimal.’ He added, ‘On a degree of difficulty scale, building a sports car is a 2. Building a high-volume affordable car is a 10.’ … The more I prodded, though, the more skeptical I became.”

The truthy car boys didn’t want to be left out of the intelligent prognosticating, adding, “Join the club Joe. And thanks for reading.” See, it’s not only New York Timers that are smart. Even car boys can identify a joke when they see one. They can even write a good joke from time to time. Exhibit A:

Think “fraud” is a new favorite word of Tesla haters? Come on, this one is timeless! Well, it goes back at least as far as 2009.

“Gawker reports that Tesla spinmeister Daryl Siry left the Silicon Valley startup because CEO Elon Musk (above) was pushing to accept deposits on the Model S sedan. The Model S (a.k.a. WhiteStar) exists only as a prototype. Tesla has no factory or financing with which to build it. When Musk announced that the DOE would approve Tesla’s loan application (they haven’t and likely won’t) and decided to accept $40K Model S deposits (next month), Siry smelled fraud and bailed.”

Good thing Siry left back in 2009, before shit hit the fan and he lost a ton of money. (Full disclosure: I don’t recall ever seeing Siry’s name before, and I definitely can’t verify if the claims above are valid. Either way, it appears he got off the ship just before it burned and sank. Lucky him.)

The writer’s historic ending to that article: “Meanwhile, anecdotal evidence from Tesla forums indicates that the real winner here: the Fisker Karma.”

Ah, indeed, the Fisker Karma.

To be fair, Fisker might be back, and the writer of that article above is still warning people that Tesla might collapse at any moment.

A few months later, here’s the title of another post on the Truth About Cars blog: “Tesla’s Model S Ponzi Scheme Rakes in $2.6M. At Least.” Ponzi scheme — clever. Who could have imagined such wit? I’m just honored to be alive at this time, to cherish the literature as it freshly rolls off the keyboards of today’s Mark Twains and George Bernard Shaws.

Okay, that’s 9 years ago, so maybe it’s not super fresh any longer. But isn’t it relevant into infinity? We can roll “Ponzi” into Tesla coverage every day forever.

The Death Watch crew also found a letter from Tesla CEO & Chairman Elon Musk to staff back in 2009 that can be carried forward to today:

“This is why I’m so concerned about the continuing leaks to media. It really hurts free communication when even minor issues are leaked and blown way out of proportion. It is nutty that a company like Tesla, which is doing really well right now (how many companies can say that they’re sold out through October?) should suffer from misleading articles on blog sites that would have no credibility, but for a purported inside leak. The leaks often aren’t even accurate!”

Good thing the media got much better about not blowing minor issues out of proportion.

Next up is a good one to end with today. The title is too perfect. Again, this story is from 2009. Here it is: “Tesla Claims Profitability: Do We Believe Them?“

That’s right — don’t believe Elon Musk or anyone else from Tesla when they tell you they’re going to turn a profit or actually just started turning a profit. Yep, fraudsters can be liars, and even if liars can be profitable, a liar is a fraud, and you simply can’t believe liars and fraudsters when they tell you they’re profitable.

By the way, if you dare venture into the comments of any of those stories linked above, you’ll find the early gems of discussions still taking place today on Twitter, Seeking Alpha, CNBC, and even under some CleanTechnica articles. It’s as if nothing has changed.

Never mind that Tesla went from building a handful of Roadsters to producing approximately 20,000 cars a month, or a rate of 240,000 cars a year.

Oh, wow, you’re still here? As a reward for your perseverance, I spent some time trying to find my first article about Tesla. We started covering Tesla here on CleanTechnica back in March 2009 with the article “The new Tesla Model S is… very sexy,” but my first article on the company wasn’t written until May 2012 when I published “Tesla Motors to Start Delivering Model S on June 22.” That was just a little more than 6 years ago — but it sure feels like decades.

This was a quote from Elon Musk back in that May 2012 article: “In 2006 our plan was to build an electric sports car followed by an affordable electric sedan, and reduce our dependence on oil. Delivering Model S is a key part of that plan and represents Tesla’s transition to a mass-production automaker and the most compelling car company of the 21st century.” Grand plans. Many were laughing. Who’s laughing now?

January 12th, 2019

I was searching for some old information on the Model X on Friday and I stumbled across interesting old news that made me reflect a bit on Tesla’s development. Then I stumbled across more. And then more. So I ended up deciding to put together this piece on some Tesla news flashbacks.

Back in 2009, a prominent auto journalist bet Elon Musk $1 million that Tesla couldn’t roll out the Model S by the end of 2012 with the specs presented. Tesla did. Elon donated $1 million to charity anyway.

Back in 2010, Toyota & Tesla announced that they’d team up on an affordable electric car. Confused? That was the Toyota RAV4 EV, which had Tesla internals and a Toyota exterior. It was a well loved car by the few people who got one into their garages, but it didn’t see many states, let alone other countries.

Back in 2011, Tesla expected that it would sell 30,000–35,000 Model S and Model X vehicles combined each year. Tesla now sells 100,000 per year.

Also back in 2011, Elon Musk projected that Tesla would show a quarterly profit in 2013. (Snicker, snicker.) It did.

Back in 2012, Tesla was very excited because it got 500 Model X reservations in 4 days! (Seriously.) My, how times have changed!

Back at the end of 2012, Tesla opened its first two Superchargers on the US East Coast.

In January 2013, we found out that Tesla had trademarked “Model Y,” which would mean that Tesla’s eventual vehicle lineup would be S-E-X-Y (back then, it was expected the Tesla Model 3 would be the Tesla Model E … before Ford blocked that from happening).

Also back in 2013, Tesla announced that it was delaying release of the Model X almost one year … because the Model S was so popular. This is something that has long been forgotten or overlooked, but it was an early sign of Tesla vehicle demand being much greater than just about everyone expected.

A couple weeks later, Tesla proudly announced that it was producing a whopping 500 Model S sedans per week. Wow! (Okay, I’m making fun now, but that was a big milestone and a multi-year series of milestones like that is what led us to today. Perhaps it won’t be that long before 90,000 Teslas a quarter seems like small fries, and even funny.)

Also back in 2013, Elon Musk said that the company’s 4th model (which had not yet been named the Model 3) would be released by 2017. Many Tesla critics laughed at that as an absurdity. Tesla did indeed release the 4th model in 2017.

Also back in 2013, we started getting word that the Tesla Model S was crushing the large luxury car competition in the US. Of course, the claims of Tesla critics and shorts back then were that the high demand was just a blip, a short-term thing, and that demand was starting to drop and Tesla would soon be in for a big hurt. Actually, the Model S continued to dominate the large luxury car segment and continued to hold the #1 spot in 2018 — by a wide margin.

In January 2014, I summarized the 13 electric vehicles coming to market that year in the USA and Europe, the: BMW i3, BMW i8, Tesla Model X, Volkswagen e-Up!, Volkswagen e-Golf, Cadillac ELR, Kia Soul EV, Mercedes-Benz B-Class Electric, Porsche Panamera Plug-in S E-Hybrid, Nissan e-NV200, and three Via Motors models (that never actually got to the consumer market). My, how times have changed!

I recently had some fun digging up old Tesla news and putting it in the context of the company’s progress to date, which can make it fascinating. I’ve also elaborated on 11 years of hyped up FUD about Tesla and claims of its imminent demise for the past decade. And I’ve explored 8 “impossible” goals the company has achieved. I forgot, though, that a reader sent along a list of his own favorite reminders back in October. It’s a great list as well, so I’m writing about it here for another round of “Tesla Flashbacks.”

In 2012, an IHS analyst seemed to kick off FUD (fear, uncertainty, and doubt) connected to the idea of Tesla killers before anyone I know of threw around the idea. He said, “several factors remain that work against the company, not the least of which is a major competitive disadvantage against efforts being made by major automakers, despite the massive influx of cash that Tesla has enjoyed.

“The $57,400-and-up $64,900-and-up 2012 Tesla Model S will be a curious proposition for a luxury-car buyer. It enters a segment (mid-size luxury sport sedans) that doesn’t see huge volumes–and one in which brand loyalty tends to be strong.

“Tesla likes to suggest that the Model S is unique and will set itself apart from competition that includes stalwarts like the BMW 5-Series, Mercedes-Benz E Class, and a dozen other models.

“Perhaps it will—if Tesla’s sales goals are not terribly ambitious, they could be met. It’s possible to sell a few thousand of anything in this country, on novelty value alone. IHS Automotive forecasts that if Tesla can get the car to market, it will likely sell at least a few thousand.

“But the idea that Tesla could sell tens of thousands of Model S sedans in the U.S. is folly. The most popular vehicles in that segment only sell a few tens of thousands themselves, with some models–Audi A6, Jaguar XF, Lexus GS–well below 10,000 sales a year.

“Remember that hybrid vehicles themselves, which are far easier to own and operate than pure electric cars, are still just 2 to 3 percent of the total U.S. market. And a recent Deloitte & Touche research note suggests that whether car buyers actually want electrified vehicles is still a matter of some debate.”

Folly indeed. Was that guy really getting paid for his analysis? Well, of course he was, as were countless other analysts saying the same thing.

I have to admit — I’ve been on a number of conference calls with industry analysts in which I was clearly in an “extreme” corner and basically there to be the “pro-Tesla” voice of the debate. As it turns out, my points bore much more fruit than the others I’ve heard over the years.

In the same interview, though, the analyst highlighted Tesla’s impressive level of vertical integration and in-house part production as well. “I wasn’t aware how much of the technology in the Model S was developed in-house.

“Tesla makes nearly everything on the Model S itself. The exceptions are some of the trickier bits, like the pedal box and steering column, which it gets from Daimler. Tesla even makes its own molded plastic parts, using machinery left by Toyota at the Fremont, California, assembly plant.”

That in-housing and ingenuity led the analyst to believe that Tesla had a better chance of survival than he once thought.

“I still think that as an automaker, Tesla needs to have a partner to survive long-term. But it has actually demonstrated that it can find partners who are interested in further tie-ups, and also that selling its own cars is not the only avenue to making money.

“I remain skeptical, however, about the market chances for the Model S and the actual demand for a $57,400-plus $65,000-plus all-electric sedan from a relatively unknown brand, when compared to the modern and future competition.”

In 2014, CNN Business/CNN Money came to the brilliant conclusion that Tesla sales were cooling off. “Tesla forecast that it would sell 35,000 of the Model S worldwide in 2014, but sales tracker Autodata estimates that U.S. sales in the first quarter rose less than 1%. … Investors are increasingly concerned about a decline in 2014 North American deliveries, according to Adam Jonas, auto analyst with Morgan Stanley.” Global sales of the Model S are now ~50,000 a year, as are sales of the Model X, and sales of the Model 3 are much higher. Those nail-biting analysts seem to have been worried about nothing.

In April 2015, one tech journalist offered a rather hilarious take on the Model S compared to new plug-in offerings from BMW. He drove a BMW i8 for a week and got a lot of attention for it. He didn’t seem to get any attention from Tesla drivers, and then came to some odd conclusions about that. “There was, however, a curious exception to all of this techno-worship: drivers of the Tesla Model S. Others rolled down a window, snapped a photo, or simply asked what it was. I shared a few fist bumps with owners of the BMW i3 and even the Chevy Volt, two other electric cars. But the Tesla drivers studiously avoided eye contact. I encountered two or three dozen over the course of a week, but no Model S driver ever acknowledged my car’s existence—a gnawing insecurity was inescapable. Tesla Motors practically invented the concept of the eco-supercar—at least at a consumer level—and it has dominated the sector for three years. But next to BMW’s i8, Tesla bore the patina of age.”

Haha. Did the writer really think Model S drivers didn’t look at him or the i8 out of insecurity? They most likely didn’t acknowledge the i8 because it doesn’t compare to a Model S in numerous key ways. That helps to explain why historical i8 sales look like a spec of dirt next to the hill of Model S sales to date.

Going on: “But BMW’s i-series, which launched in Germany at the end of 2013, has obliterated any doubt as to whether Germany will be a contender in what I call the Great Race for electrification. Indeed, although Porsche sells plug-in versions of its Panamera and Cayenne SUV, the i8 is arguably the first real challenger to Tesla’s eco-chic Model S.” I could create a sales chart to demonstrate how laughable that idea was, but honestly, it’s not even worth the time. The i8 is a pretty car and is fun in its own way, but it’s no Model S competitor and never had a chance of being one. (For the record, I own a BMW i3 and love it, and do love the styling of the i8, but the reason I have an i3 is that its selling price on the used market was so far below its original MSRP that it felt like a steal for such a fun car. Also, it was the first electric car I drove, and I assume there’s something like “first love” there for me.)

In a 2015 article on BMWBlog (which, admittedly, is inherently going to be pro BMW), the writer was enthusiastically covering an experimental BMW plug-in hybrid with oodles of power. He wrote, “Now if/when Elon Musk hears about this, he will inevitably point to the fact that not only is ‘The Thing’ experimental and he has experimental projects as well, but that ‘The Thing’ uses a gasoline engine in tandem with electricity while the Model S does not. However, I think that’s a selling point for BMW’s technology as over the Model S. Plug-in hybrids offer more flexibility as they can be filled with gasoline as needed, so range anxiety no longer exists. Although, Mr. Musk claims to be eliminating range anxiety, there’s simply no scenario where a pure electric car has the range of a plug-in hybrid.”

If you read CleanTechnica regularly, a certain story I published last weekend might have popped into your mind reading that. It turns out that Tesla sold more Model 3s in 2018 in the USA than all other automakers sold all of their plug-in hybrids. The Model 3 didn’t just crush BMW’s plug-in hybrid models. It crushed BMW’s + GM’s + Ford’s + Daimler’s + Toyota’s + Honda’s + Chrysler’s + Mitsubishi’s + Hyundai’s + Kia’s + Volkswagen’s + Audi’s. Tell me again, how does a plug-in hybrid powertrain compete against a well designed fully electric powertrain?

In August 2015, Reuters hyped that, “The Silicon Valley automaker is losing more than $4,000 on every Model S electric sedan it sells, using its reckoning of operating losses, and it burned $359 million in cash last quarter in a bull market for luxury vehicles.” Of course, that was a misrepresentation of the story, or a misleading way to communicate what the company was doing. Tesla was selling thousands of Model Ss per month, each of which was making the company money. (In fact, Tesla has long had fairly high gross margins on the Model S.) At the same time, Tesla was investing a ton of money into rapid growth, continuous development that would lead to where it is today — selling tens of thousands of cars a month and profitable.

Going back no further than February 2016, we have to end with one of our favorites. That would be Bob Lutz, the former vice chairman of GM (among other things), claiming that the Tesla Model X would be impossible to build and that Tesla’s whole business model didn’t make sense. “Tesla’s business model is upside down…their costs have always been higher than their revenue,” Lutz told CNBC. “They always have to get more capital, then they burn through it.

“While [Tesla’s] car is excellent, the business has always been lousy. Now, it’s super lousy because the generic demand for electric vehicles is down. And here’s why this is going to kill Tesla: whether there’s consumer demand for electric vehicles out there or not, the major OEMs like Ford, GM, Toyota, Volkswagen … they have to build electric cars — a certain number — in order to satisfy the requirements in about half of the states. Those have to be jammed into the marketplace, otherwise they can no longer sell SUVs and full-size pickups and the stuff they really make money on. That is going to generically depress the prices of electric vehicles. …

“The Model X appears to be unbuildable with those automatic gull-wing doors, which everyone in the industry always said were not going to work.”

The year before, Lutz said that Tesla faced “[the] trifecta of doom … bleeding cash, securitized assets, and mounting inventory.”

Shhh, nobody tell Bob that Tesla now mass produces the Model X (selling ~50,000 per year), the doom dissipated and profitability took its place, other automakers still aren’t competing with Tesla, demand for electric cars has risen rather than dropped, and Tesla’s business model seems to be very right-side up.

Okay, let’s be fair for a moment — it was easy to not understand Tesla’s advantage and inherent prowess back in the day, or even a few years ago. How could everyone know what Tesla was capable of and why its vehicles were and would be so much more competitive than those of other automakers? Well, actually, many followers did understand all of that. They were often called brainless, Kool-Aid drinking, cultish fanboys. They were discounted by analysts and “auto experts.” They were pushed into a dark corner by most of the media. (Actually, it’s hard to think of any major media outlet that didn’t assume we belonged in a dark corner.) We explained the advantages in the specs, in a well designed electric powertrain, in a fully electric corporate focus, in constant hardware and software innovation in rapid development cycles, in Tesla’s in-housing of core components, and so on. But we were just fanboys. What else would we say?

Perhaps with this next round of Tesla targets it’s time for the major media to spend time learning from those people who know the most about Tesla, and can provide an independent voice on the company without throwing in unwarranted pessimism. Or just keep on doing what you’ve been doing.

Tags: Bob Lutz, Tesla, Tesla Death Anniversary, Tesla Death Watch, Tesla Model 3, Tesla Model S, Tesla Model X, Tesla Roadster, Tesla sales, Tesla stock

Zachary Shahan Zach is tryin' to help society help itself (and other species). He spends most of his time here on CleanTechnica as its director and chief editor. He's also the president of Important Media and the director/founder of EV Obsession and Solar Love. Zach is recognized globally as an electric vehicle, solar energy, and energy storage expert. He has presented about cleantech at conferences in India, the UAE, Ukraine, Poland, Germany, the Netherlands, the USA, and Canada. Zach has long-term investments in TSLA, FSLR, SPWR, SEDG, & ABB — after years of covering solar and EVs, he simply has a lot of faith in these particular companies and feels like they are good cleantech companies to invest in. But he offers no professional investment advice and would rather not be responsible for you losing money, so don't jump to conclusions.

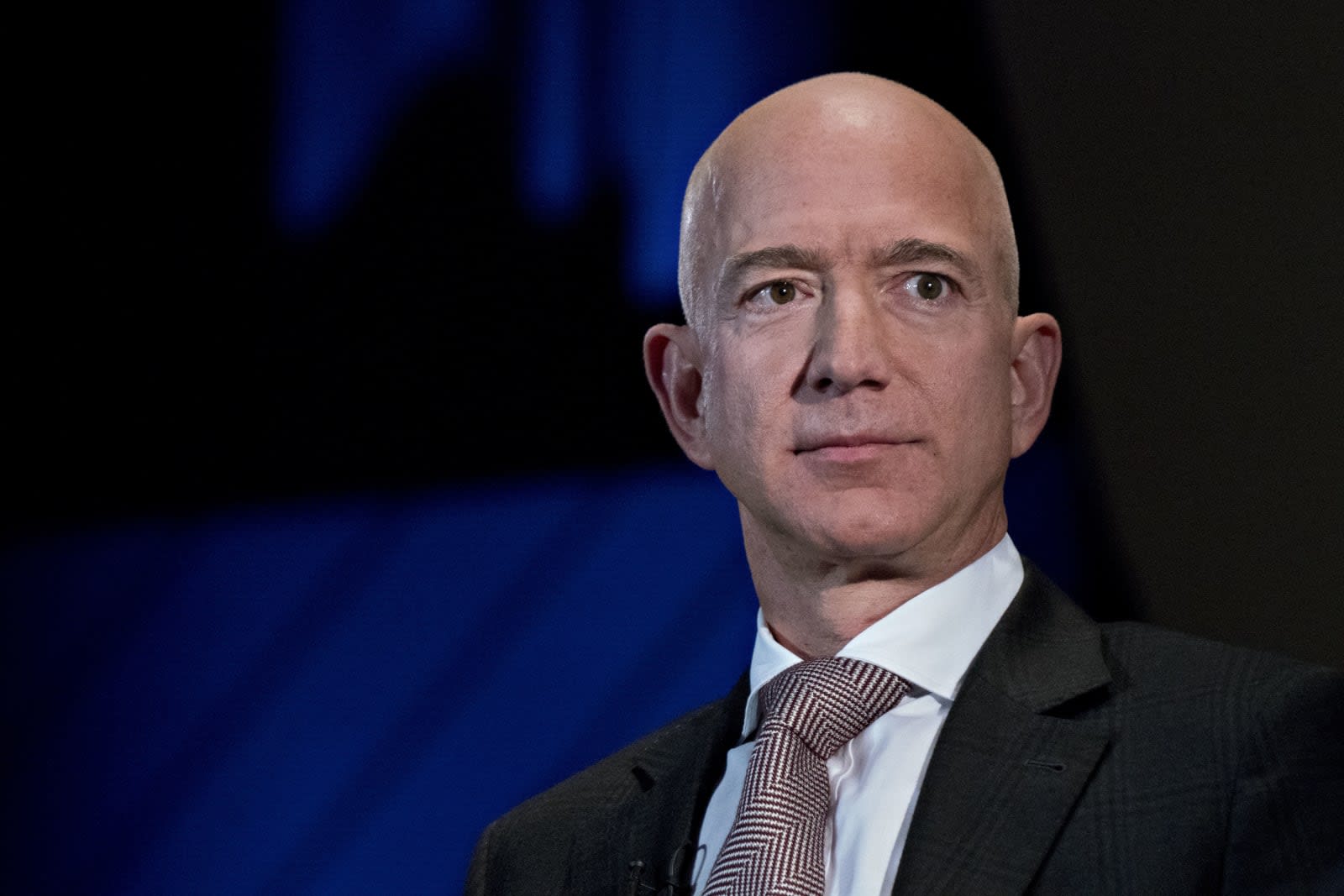

FILE PHOTO: Jeff Bezos, president and CEO of Amazon and owner of The Washington Post, speaks at the Economic Club of Washington DC's "Milestone Celebration Dinner" in Washington, U.S., September 13, 2018. REUTERS/Joshua Roberts/File Photo

WASHINGTON (Reuters) - The publisher of the National Enquirer on Sunday said its reports on Amazon Chief Executive Jeff Bezos’ private life were based on information from a single source, the brother of Bezos’ girlfriend, Lauren Sanchez.

The statement from American Media Inc. followed publication by Bezos security chief Gavin De Becker of an article in the Daily Beast in which he said the government of Saudi Arabia had accessed private information from Bezos’ phone.

While De Becker said in the article that there was “high confidence that the Saudis had access to Bezos’ phone,” it was “unclear to what degree, if any, AMI was aware of the details.”

Nevertheless, AMI released a statement saying its reports on Bezos’ affair with Sanchez were based solely on information provided by Michael Sanchez, “who tipped the National Enquirer off to the affair on Sept. 10, 2018, and over the course of four months provided all of the materials for our investigation.

“There was no involvement by any third party whatsoever,” it added.

Gavin de Becker & Associates did not immediately respond to a request for comment. A representative for the Saudi embassy in Washington did not immediately respond to a request for comment.

Reporting by Howard Schneider; additional reporting by Humeyra Pamuk; Editing by Dan Grebler

Jeff Bezos' accusations of blackmail and extortion extend beyond just the National Enquirer and its parent AMI. Bezos' investigation team has determined "with high confidence" that Saudi Arabia had access to the Amazon chief's phone. Team leader Gavin de Becker pointed to a number of factors leading to the conclusion. Most notably, he rejected the Enquirer's claims that Michael Sanchez (the brother of Bezos' lover Lauren) was the sole source for the info. Sanchez told Page Six that the Enquirer had already seen text messages when it contacted him to investigate Bezos' possible affair -- there was another source, and de Becker's group believes Saudi Arabia is the most likely culprit given its methods, motivations and connections to AMI.

The Saudi government reportedly relied extensively on covert phone surveillance as part of the murder of Washington Post journalist Jamal Khashoggi, according to the New York Times and de Becker's expert consultants. And when the Post (owned by Bezos) started covering Khasoggi's murder in earnest starting October 2018, the Saudis started attacking Bezos and de Becker with organized social media attacks and threatened boycotts.

There's also a "close relationship" between Saudi regent Mohammad bin Salman and AMI chairman David Pecker, according to de Becker. The chairman brought bin Salman's intermediary Kacy Grine to a private meeting with President Trump, while the company also created a magazine to sell bin Salman to the US with Grine's help. The implication, as you might guess, is that Saudi Arabia intended to retaliate against Bezos and the Post using the Enquirer as a willing conduit.

AMI has insisted that it "acted lawfully" in reporting on Bezos, while the Saudis have denied both involvement in the Bezos incident and bin Salman's involvement in Khashoggi's murder. Not that this will necessarily help them much. De Becker has submitted the results to federal officials investigating AMI's actions, and it's up to them to decide whether or not Saudi Arabia and AMI were compromising Bezos' phone.

March 31st, 2019 by Kyle Field

Tesla recently invited CleanTechnica to its automotive factory in Fremont, California, for an exclusive tour that took us behind the scenes in one of the largest manufacturing facilities in the world. This is the factory that serves as the beating heart of Tesla’s automotive business.

From the outside, the factory itself spans several city blocks, with numerous smaller facilities in the blocks and miles surrounding the factory to add onto the Tesla fun. For example, Tesla’s seat factory is just 2.6 miles down the road. We also toured that factory and will have much more to say about the place where Tesla builds all of the seats for its vehicles — and why it’s so special.

Tesla is taking over Fremont, and even a cursory tour of the area highlights how fast the company is growing and the benefit of pulling all of Tesla’s various tasks into a single Gigafactory location. After months of planning, CleanTechnica’s Zachary Shahan, Chanan Bos, and I rolled up to the gates of the factory on a crisp March morning and took it all in.

The factory proper is nearly ¾ of a mile, or just over 1 kilometer long, and sits like the great ice wall from Game of Thrones across the property. Its white walls are accentuated by the occasional pop of red and large TESLA logos to shout out to the world and the nearby freeway what’s happening inside.

Upon entering the factory, we found ourselves in an open-concept office space, with random single-person working pods referencing Harry Potter, like the “Chamber of Secrets,” along the sides. There was also the usual assortment of huddle rooms and conference rooms. Unfortunately, we didn’t see any of Willy Wonka’s oompa loompas running around, or magical unicorns farting out showers of 2170 batteries. (Maybe next time.)

It was just a bunch of people working their tails off to move the business forward — designing vehicles, building out secretive new Autopilot hardware chipsets, and patching together the latest Autopilot release. It’s all in a day’s work at Tesla. The office looked clean and well branded, with a thick dose of coffee punctuating the otherwise stale office smell. Recognizing the vast thirst for coffee across the company, Tesla even has its own coffee roast, which is rumored to still available from some of the caffeination stations buried in the depths of the factory.

Team CleanTechnica donned our personal protective equipment and headed into the factory proper, where we were quickly greeted with the familiar sounds of forklifts, conveyors, and motors, punctuated by the occasional pop of a weld from the nearby body shop. Hopping on an electric cart, we zipped over to the General Assembly for Model 3 and took a few minutes to look at the Model S assembly lines.

General Assembly is where the painted body of the car comes to get all the fun stuff that humans actually interact with. That includes the wiring, carpet, dash, monitor, center console, seats, and the like. Hundreds of parts and sub-assemblies are bolted onto and into the vehicles as they move down a linear production line that has been selectively automated to eliminate ergonomically incorrect tasks and the need to lift heavy or awkward parts, or simply to speed up the process.

In the Model 3 General Assembly lines, the balance of automation vs. human effort had clearly been worked out as Tesla sought to make the assembly process not only faster and more predictable, but also more friendly for humans. Generally speaking, Tesla found that machines are great at working with parts that are always the same size and in the same place, like metal, bolts, batteries, battery packs, hard plastics, and such. When it comes to working with fabrics, belts, wires, and the like, humans are better.

Location of the Tesla Model 3 “marriage,” where the lower battery and motor assembly is mounted to the vehicle body. In this picture, you can see the bottom “skateboard” of a car and a Model 3 body moving toward a location above it where the two will be married. Image credit: Kyle Field | CleanTechnica

There is a strong case for using robots where lifting, placing, and bolting parts might result in repetitive strain injuries. The placement and fixing of the heavy dash assembly into the car is a great example. Machines can easily and quickly place the dash into the car and bolt it in predictably, time after time, without having to wonder if every bolt was torqued correctly. Tesla actually tracks each and every individual bolt and part used in a vehicle, along with the torque specs that were used when fixing them to the vehicle.

Tesla’s Manufacturing Operating System was built completely in-house and has evolved over time as the company grew. It currently supports nearly all of the company’s manufacturing equipment. The custom-built operating system has allowed Tesla to fine-tune its equipment and processes. It clearly comes at a cost, as every change must be vetted and developed internally, but the upshot of the additional internal complexity is flexibility. Tesla can quickly come up with a new improvement or change to its products, equipment, or centerlines and implement it before another automaker would even be able to get a formal proposal together to send to a vendor.

This flexibility and agile design methodology is common to hear about in just about any company with an IT department, but to see it playing out and actually, mostly working in a manufacturing plant is unheard of outside of Tesla. Again, people talk about what they call in the industry “extreme manufacturing,” but coming from nearly two decades in traditional manufacturing with 5 years in applied IT, actually seeing it functioning in the real world was impressive.

Tesla isn’t perfect, so don’t read this as if we’re stating that Tesla has automotive manufacturing so dialed in that nobody could ever do it better. It’s hardly that. Temporary engineering workstations were set up in the middle of the production line to troubleshoot the equipment. When we were there, I noticed line of partially finished vehicles had been pulled out of the production flow for body shaping issues to be corrected before moving along to painting. The factory, like every other factory I have visited, is a living, breathing entity.

The lesson we gleaned is that, while Tesla is far from perfect at manufacturing, it is, at the same time, improving at a rate that has never been seen before in automotive manufacturing history. The variability of a normal production line in any other factory in the world is compounded at Tesla by the stream of continuous improvements that are fed into the process every day, every week. This doesn’t just apply to the manufacturing process — the machine that builds the machines — but also its products. We heard and saw this play out time and time again throughout the day.

Tesla is constantly improving. Every day, its seats are getting better than the day before. Each and every day, its software is improving, iterating, evolving. Its welding has been tweaked, its battery chemistry is constantly being refined, battery module designs change, chassis, safety, steering, power output … you name it. That’s why Tesla doesn’t have model years for its vehicles. They are constantly evolving. Each day, or at least each week, Tesla is producing a different car than it was producing a week before.

Everything and anything in the company and in the car is up for debate. There are no so-called sacred cows that cannot be touched. That principle reared its head with the all-out push to release the $35,000 Tesla Model 3 Standard Range, which resulted in the very public statement that Tesla would be closing many of its retail stores and would be switching to 100% online sales, and that it would be slashing prices across its lineup at the same time. A few simple days of number crunching later, Tesla walked its position back a little, raising vehicle prices back up a few percent. Overall, a healthy equilibrium is reached, but the journey to get there is often bumpy, stressful, and unpleasant — especially if you are not accustomed to this style of business.

Tesla takes its vehicles all the way from rolls of aluminum to completed vehicles at its factory. That all starts with its massive Schuler press servo tandem line. This is the stamping press that’s tasked with stamping out body panels for the Tesla Model 3. While there are 35 of these presses in Europe, Tesla’s Schuler is the first of these high-precision, high-throughput presses in the US.

The Schuler press is so large that it is hard to take in at a single glance. We walked around the Schuler press and were able to see a changeover of the dies it uses to stamp out parts. Matched sets of dies are used in the Schuler to stamp out uniform aluminum body parts even faster than the rate claimed by the manufacturer, thanks to numerous improvements made by Tesla after commissioning the press. (Watch the 4 second video clip above for a visual on this.)

The Schuler may be the first of its kind in the US, but Tesla didn’t use that as an excuse to ramp up production slowly. Instead, Tesla’s team installed and commissioned the Model 3 servo press in ~25% less time than the fastest installation Schuler had ever done before. And that was just the starting point. Tesla proceeded to scrutinize every single piece of the press, making small tweaks and changes along the way.

At the discharge of the press, Tesla completely reworked the conveyors in order to fit more functionality into less space. The company did this by replacing the two discharge conveyor belts that came with the press with four shorter belts that fit better into the available space.

Changes like this and more allowed Tesla to increase the rate of the press from 12 strokes per minute to 14 strokes per minute, a 16% improvement. That translates to more throughput from an extremely expensive piece of equipment and less capital required to scale up production. Putting that into context, Tesla can now produce body panels and stampings from the Schuler press at twice the rate as its Model X stamping press line and a mind boggling four times the rate of the older Model S production lines.

After coming out of the stamping press, body panels and stampings are then manually inspected by a team of workers, with any imperfections being buffed out or flagged for correction before being filed into waiting racks. The racks of finished parts are then stored in an adjacent building until the body shop is ready to start welding them together into the body of a car.

A select set of the finished parts are pulled for quality assurance testing, where they are run through a vision system that checks them against a digital template. The multiple levels of quality checks aim to eliminate defects resulting from the press section, which translates into a better product for customers and a lower total cost to manufacture for Tesla. Quality is one of those metrics that we can all get behind.

After the press section, we headed into the heart of the beast. The tour path twisted and turned so much that my head began to swim, and before I could get my bearings, the process engineer that would be our guide emerged with a smile on his face. He explained that he would be taking us on a tour of the body shop, which is, contrary to popular belief, not the part of the shop where Elon and the other Teslateers go to get ripped.

The body shop is, in fact, where Tesla turns body panels into fully assembled auto bodies. Each section of the shop is comprised of densely packed robots that look like they came straight out of the latest Transformers movie. In each section, an army of these robots attack a specific set of tasks that grab body parts and inspect, fit, weld, or glue them together into a finished vehicle frame.

Tesla told us that the Model 3 body line is 90% automated and has over 1,000 robots, which is not hard to believe after visiting the factory. That figure takes on a completely new meaning when you see all those robots in real life, building cars, moving parts, and welding seams. As the Model 3 bodies are assembled, a team of 47 robots are hard at work at a dozen inline scanning stations that measure 1,900 points in every auto body to ensure that the cars coming off the line meet Tesla’s exacting standards. Take that, panel gaps.

Building on the philosophy described higher up in this article, where automation is well suited to tasks that involve rigid parts and repetitive tasks that might be ergonomically unfriendly or could result in high-impact quality variations, the body shop is all about automation. Body panels are fed into the process from storage racks and are quickly assembled like pieces from a Lego Technic set, with arcs of welding slag flying through the air (behind the guards) punctuating the process.

As we moved along the body shop production line, beautiful polished metal bodies emerged from the swirl of robots, evoking a smile of recognition from our group. The team of Transformer robots were extremely effective in turning a mass of body panels into an assembled thing that had a striking resemblance to my very own Tesla Model 3 out in the parking lot.

We took a stroll down the street to meet with some of Tesla’s interior and seating experts at the company’s “second-to-none” seat factory. Tesla’s decision to manufacture its own seats was yet another sharp diversion from traditional automotive manufacturers. It is yet another example of Tesla’s ability to pull difficult production tasks in-house, and the result is a one-of-a-kind level of vertical integration in its seat manufacturing.

The decision was initially made in response to a healthy dissatisfaction with the status quo. There are four primary seat builders that build seats for the auto industry, but in typical Tesla fashion, they found that they needed higher quality, lower cost, and more flexibility than the suppliers could provide. So, Tesla brought seats in-house by hiring some of the best in the interior automotive and seat manufacturing industries.

Their Model 3 seat factory was initially built with capacity for two seat assembly lines with a total production capacity of 10,000 seats per week (5,000 per line). However, since starting up its first assembly line, Tesla has been able to squeeze out 7,000 seats per week from the first single line. That is especially relevant when we look at the high percentage of shared components between the Model 3 and the recently unveiled Model Y.

That translates to a 40% improvement in throughput from the single line and has allowed Tesla to continue to ramp up its automotive production without having to install the second line. Though, that day is surely approaching as Model 3 production continues to ramp up. CapEx is also positively affected, as Tesla could presumably achieve the same rate on the second line, effectively buying two lines and getting nearly a third line worth of production capacity for free, thanks to the improvements it made on the first two lines. Zach will soon publish a full piece on the wonders of the seat factory alone.

Stay tuned here on CleanTechnica for a comprehensive rundown of everything we experienced at the factory, including some fantastic video footage.

Related: Tesla’s Vertical Integration Unlocks Hidden Flexibility & Innovation — #CleanTechnica Field Trip

Tags: California, Fremont, Fremont California, Tesla, Tesla factories, Tesla Fremont factory, Tesla Model 3, Tesla Model S, Tesla Model X, Tesla Seat Factory

Kyle Field I'm a tech geek passionately in search of actionable ways to reduce the negative impact my life has on the planet, save money and reduce stress. Live intentionally, make conscious decisions, love more, act responsibly, play. The more you know, the less you need. TSLA investor.